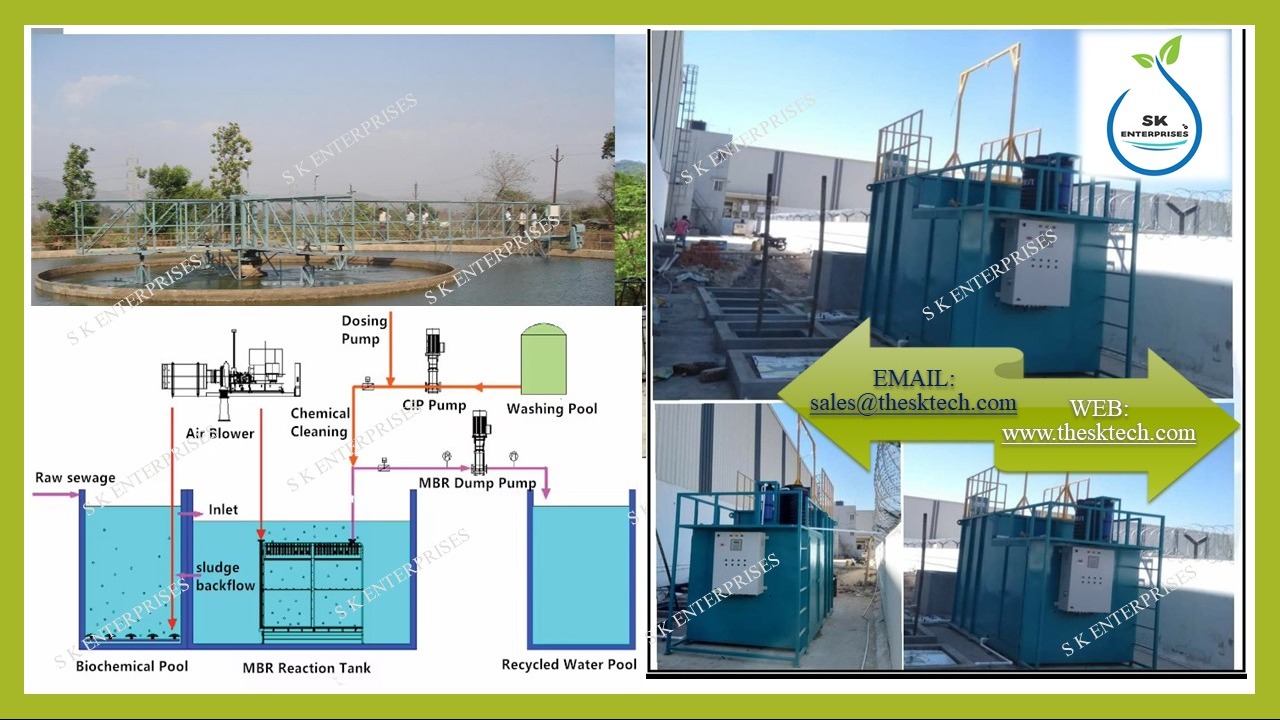

An MBR (Membrane Bioreactor) plant is a wastewater treatment technology that combines biological treatment with membrane filtration. It utilizes microorganisms to break down pollutants and then uses membranes to filter out solids, producing high-quality effluent. MBR plants are widely used in municipal and industrial settings for wastewater treatment. How MBR Plants Work: 1. Biological Treatment: Raw wastewater is introduced into a biological reactor, where microorganisms, like bacteria, degrade organic pollutants. This process is similar to conventional activated sludge treatment. 2. Membrane Filtration: The treated wastewater then passes through semi-permeable membranes, like microfiltration or ultrafiltration membranes, which filter out remaining solids and microorganisms. 3. High-Quality Effluent: The resulting effluent is of high quality, with reduced levels of suspended solids, turbidity, and contaminants. Advantages of MBR Plants: High-quality effluent: MBRs produce cleaner effluent than conventional activated sludge processes. Independent control of solids retention time and hydraulic retention time: This allows for better control over the biological process. Smaller footprint: The compact design of MBRs, due to the use of membranes, results in a smaller footprint compared to traditional plants. Robustness to load variations: MBRs can handle fluctuations in wastewater flow and composition. Reduced energy consumption: Compared to some other treatment methods, MBRs can be more energy-efficient. Lower operating costs: MBRs often have lower operating costs, including lower chemical usage. Types of MBR Membranes: Hollow fiber membranes: These membranes are commonly used in MBR systems due to their high surface area and ease of installation. Flat sheet membranes: Flat sheet membranes are another type of membrane used in MBR systems, offering a simple and efficient filtration process. Ceramic membranes: Ceramic membranes are known for their durability and high chemical resistance, making them suitable for various wastewater applications. Tubular membranes: Tubular membranes are another type of membrane used in MBR systems, offering a robust and efficient filtration process.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

An MBR (Membrane Bioreactor) plant is a wastewa...

2025-06-09T10:10:09

An MBR (Membrane Bioreactor) plant is a wastewater treatment technology that combines biological treatment with membrane filtration. It utilizes microorganisms to break down pollutants and then uses membranes to filter out solids, producing high-quality effluent. MBR plants are widely used in municipal and industrial settings for wastewater treatment. How MBR Plants Work: 1. Biological Treatment: Raw wastewater is introduced into a biological reactor, where microorganisms, like bacteria, degrade organic pollutants. This process is similar to conventional activated sludge treatment. 2. Membrane Filtration: The treated wastewater then passes through semi-permeable membranes, like microfiltration or ultrafiltration membranes, which filter out remaining solids and microorganisms. 3. High-Quality Effluent: The resulting effluent is of high quality, with reduced levels of suspended solids, turbidity, and contaminants. Advantages of MBR Plants: High-quality effluent: MBRs produce cleaner effluent than conventional activated sludge processes. Independent control of solids retention time and hydraulic retention time: This allows for better control over the biological process. Smaller footprint: The compact design of MBRs, due to the use of membranes, results in a smaller footprint compared to traditional plants. Robustness to load variations: MBRs can handle fluctuations in wastewater flow and composition. Reduced energy consumption: Compared to some other treatment methods, MBRs can be more energy-efficient. Lower operating costs: MBRs often have lower operating costs, including lower chemical usage. Types of MBR Membranes: Hollow fiber membranes: These membranes are commonly used in MBR systems due to their high surface area and ease of installation. Flat sheet membranes: Flat sheet membranes are another type of membrane used in MBR systems, offering a simple and efficient filtration process. Ceramic membranes: Ceramic membranes are known for their durability and high chemical resistance, making them suitable for various wastewater applications. Tubular membranes: Tubular membranes are another type of membrane used in MBR systems, offering a robust and efficient filtration process.

2025-06-09T10:10:09

Keywords

- utilizes microorganisms

- membranes results

- ultrafiltration membranes

- semipermeable membranes

- membrane filtration

- handle fluctuations

- compact design

- contaminants advantages

- reduced levels

- resulting effluent

- industrial settings

- wastewater flow

- treated wastewater

- high quality

- biological reactor

- remaining solids

- wastewater treatment

- mbrs due

- efficient filtration process

- wastewater treatment technology

- combines biological treatment

- treatment methods mbrs

- high surface area

- mbr systems due

- load variations mbrs

- solids retention time

- suspended solids turbidity

- mbr systems offering

- lower operating costs

- traditional plants robustness

- smaller footprint compared

- hydraulic retention time

Submit Your Enquiry