Description

Product details

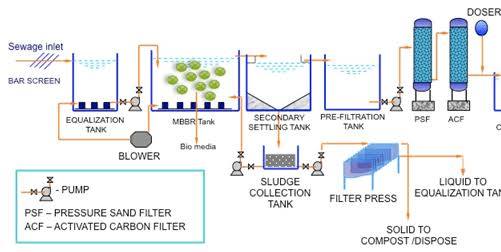

An MBBR STP is a Moving Bed Biofilm Reactor (MBBR) based Sewage Treatment Plant. This system uses a biological wastewater treatment process where microorganisms, which break down pollutants, grow on free-floating plastic carriers called bio-media. How an MBBR STP works Pre-treatment: Before entering the MBBR tank, wastewater goes through pre-treatment steps like screening and grit removal to protect downstream equipment. MBBR biological treatment: Wastewater flows into an aeration tank filled with thousands of small, free-floating plastic media. An aeration grid supplies oxygen, which keeps the media in constant motion and provides oxygen for microbial growth. Biofilm activity: Microorganisms attach to the surface of the bio-media and form a biofilm. This dense biofilm breaks down organic matter and other pollutants in the wastewater. Clarification: After biological treatment, the water passes through a clarifier or settling tank. Retention screens at the tank outlet prevent the carrier media from leaving while allowing the treated water to pass. Any remaining solids are removed during this stage. Disinfection: The final effluent may undergo additional polishing or disinfection before being discharged or reused. Key components Aeration tank/reactor: The primary basin where the biological treatment takes place and the carriers are suspended. Bio-carrier media: Small, specifically designed plastic carriers, usually made from high-density polyethylene (HDPE), that provide a large surface area for biofilm growth. Aeration system: Fine or coarse bubble diffusers supply oxygen to the microbes and keep the carriers moving within the tank. Retention screens: Screens at the tank's outlet prevent the carrier media from escaping while allowing treated water to pass. Clarifier: A tank for settling and removing any residual suspended solids after biological treatment.